Quality At The Core For Every Spindle Repair

When it comes to spindle repairs, long-lasting performance and reliability depend on precision machinery. A spindle is essential for operational success. That’s why our approach to spindle repair goes beyond simple fixes. We prioritize quality and thorough testing to deliver solutions that keep your equipment running at its best.

Our commitment to excellence extends to every repair we undertake, regardless of the spindle brand. By leveraging advanced techniques and extensive expertise, we provide results that exceed expectations and help minimize costly downtime.

Why Testing Matters in Spindle Repairs

The performance of a spindle can significantly impact the productivity and efficiency of your operations. That’s why comprehensive testing is at the heart of our repair process. Through rigorous assessments, we ensure that every spindle leaving our facility is restored to optimal performance.

By identifying potential issues before they arise, our testing process delivers reliability and peace of mind. This proactive approach helps reduce unexpected failures, ensuring your equipment continues to perform seamlessly.

Repair for Makino JET 50 Spindle

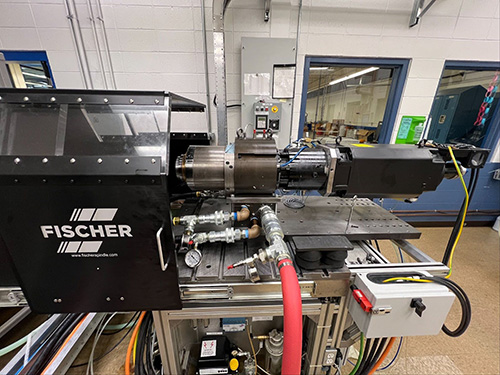

Take, for example, the Makino JET 50 spindle. At FISCHER, this repair process goes beyond a simple fix. It involves a complete assessment designed to guarantee the spindle operates at peak performance once it’s back in service. Our team invests the necessary time and care to ensure every spindle meets our high-quality standards, providing clients with reliable, long-lasting solutions.

What Sets FISCHER USA Apart

We pride ourselves on delivering the key points critical to spindle repair customers:

- Fast Turnaround Times: We understand the importance of minimizing downtime. Our streamlined processes ensure repairs are completed efficiently.

- Comprehensive Support: We provide exceptional service for all spindle brands, ensuring every client receives the same high-quality care.

- Reliable Results: Every repair is backed by thorough testing to ensure long-term performance and durability.

These strengths demonstrate our dedication to providing solutions that our clients can count on.

Customer Benefits of FISCHER’s Spindle Repairs

Our commitment to quality translates into meaningful benefits for our customers:

- Minimized Downtime: Reliable repairs ensure your equipment stays operational, reducing costly interruptions.

- Enhanced Productivity: High-quality spindle performance directly supports your operational efficiency.

- Peace of Mind: Comprehensive testing ensures that every spindle operates at optimal levels, giving you confidence in your equipment.

Contact FISCHER for Spindle Repairs

Whether you need repairs for your existing equipment or ongoing spindle maintenance, FISCHER USA is here to help. Visit our spindle maintenance page and spindle repair page to learn more about our services, or contact us today to discuss your repair needs. Let us show you how FISCHER delivers reliable, high-quality solutions for all spindle brands.