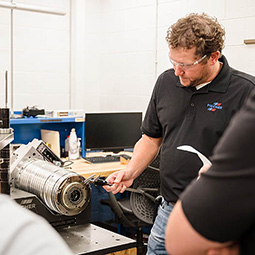

Spindle Repair & Services Gallery

Within our expansive 38,000 square foot facility, designed to cater to all your spindle repair needs, we proudly offer a comprehensive range of top-notch services. Our dedicated team of experts is fully equipped to handle every aspect of design, production, testing, and spindle repair for all makes and models, regardless of their complexity or type.

When it comes to our esteemed spindle repair process, we leave no stone unturned. It all begins with a meticulous inspection, where we closely examine various critical factors such as shaft run-out values, toolholder clamping force, electrical tests, sensor functionality, and the cooling circuit flow. This thorough examination allows us to craft a detailed Spindle Analysis Report, complete with high-resolution photos and a comprehensive breakdown of the necessary repairs required for your spindle.

Once you have received the Spindle Analysis Report and are ready to proceed, our skilled technicians will ensure that every broken part and worn-out bearing is promptly replaced with the utmost precision and attention to detail to achieve like-new condition. We believe in going the extra mile to ensure the longevity and optimal performance of your spindle.

But our commitment to excellence doesn't stop there. Unlike other repair services, we don't simply perform a standard spindle run-in after the repairs are completed. Instead, we take it a step further by operating and carefully testing the repaired spindle as if it were installed in your machine. This rigorous testing process allows us to guarantee that the spindle is functioning flawlessly and will seamlessly integrate into your operations.

Once the repaired spindle has passed our stringent testing protocols, we take every precaution to ensure its safe transportation back to your company location. With our reliable shipping methods and careful packaging, you can rest assured that your like-new spindle will arrive in pristine condition. And to provide you with complete peace of mind, we offer a generous 6-month warranty on all our repaired spindles.

If you're in need of spindle repair services that prioritize quality, precision, and attention to detail, don't hesitate to reach out to our dedicated team. We are always ready to discuss your specific spindle repair needs and provide you with the exceptional service you deserve.

Click a gallery section below to review more photos:

Spindle Manufacturing |

Milling Head Repair Area |

Spindle Assembly Area |

Test Room Area |

Spindle Disassembly |