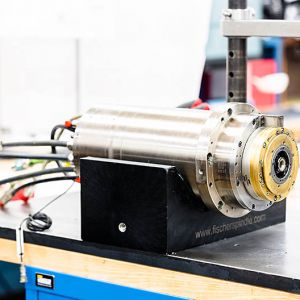

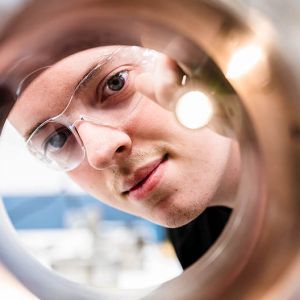

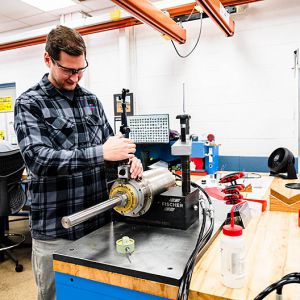

Spindle Disassembly

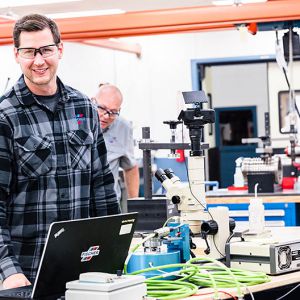

At FISCHER USA, our 85 years of experience in high-precision spindle manufacturing has cultivated an unparalleled expertise in spindle repair. Our commitment to restoring your spindle to its original performance is founded on a systematic, transparent, and meticulous process. We go beyond simple part replacement to provide a comprehensive solution that ensures long-term reliability.

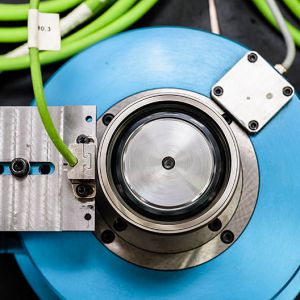

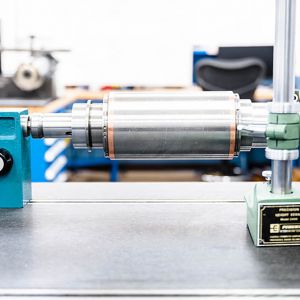

The moment your spindle arrives, it is subjected to a thorough inspection. We don't just look at the obvious; our skilled technicians meticulously evaluate every aspect of the unit. This includes a run-in test (where possible) to gather baseline data on vibration, heat, and noise, followed by a detailed visual and electrical inspection. Once the initial diagnosis is complete, we proceed with disassembly in a clean, controlled environment. Every component is carefully removed, cleaned, and cataloged. This step is crucial for identifying the root cause of the failure, whether it's a worn bearing, a failed seal, a damaged winding, or a compromised shaft. It then moves on to the spindle assembly area.