Repair Spotlight: Restoring a Critical GMN HCS 270 Spindle

At FISCHER USA, we are known worldwide for the quality and precision of the spindles we manufacture. What many companies in the manufacturing, aerospace, and automotive sectors may not realize is that our expertise is not limited to our own brand. We are a dedicated, trusted partner for comprehensive 3rd party spindle service as well.

If your critical machine tool spindle carries a name other than FISCHER, our certified technicians have the knowledge, the tools, and the commitment to bring it back to OEM-level performance and reliability.

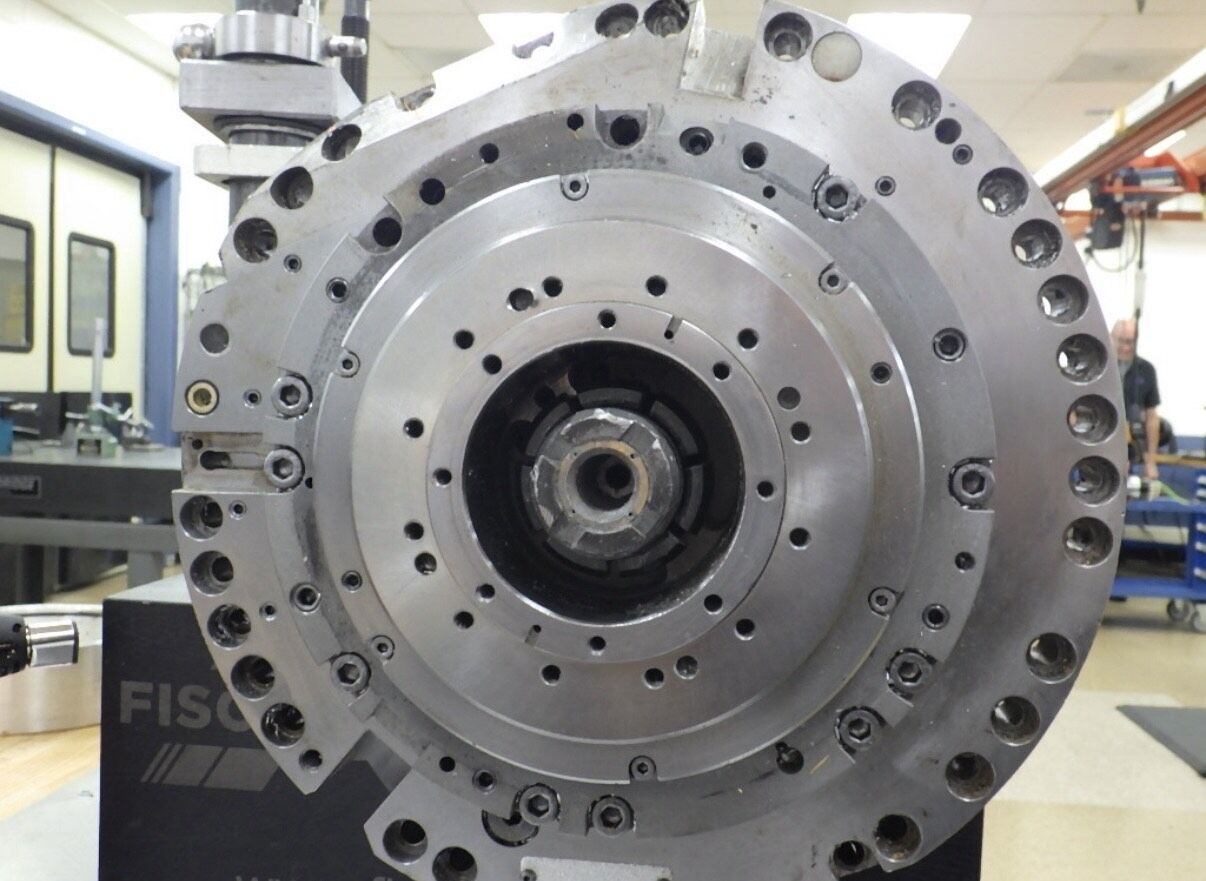

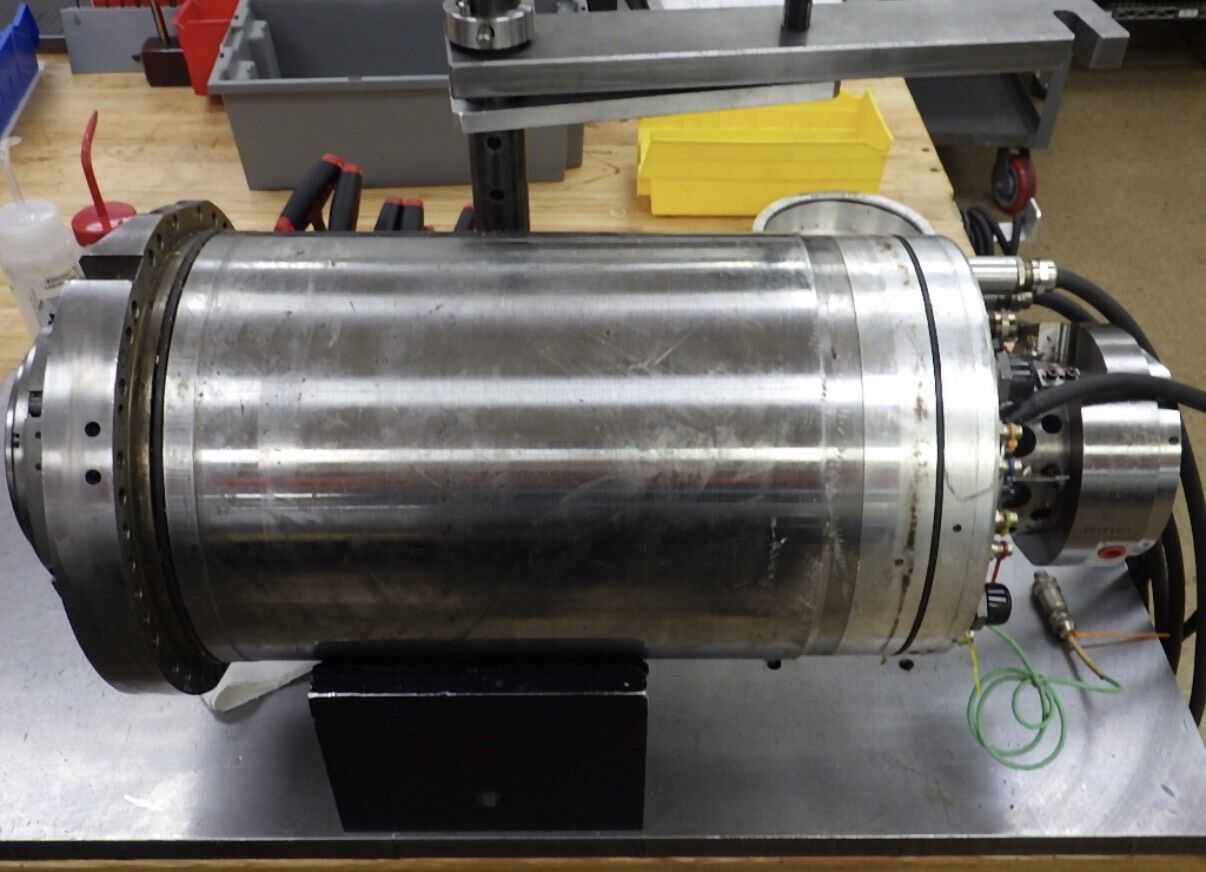

A recent repair highlight perfectly demonstrates our capabilities in spindle repair service. Our team recently completed a full repair on a GMN HCS 270 – HSK-A100 spindle. This model is commonly found on DMG machines and is a workhorse in demanding applications, including the aerospace industry, where precision and uptime are non-negotiable.

The spindle arrived at our facility requiring a complete rebuild. Our process ensured every component was addressed with the utmost care and precision:

-

Precision Inspection & Analysis: We started with a thorough, component-level inspection to accurately diagnose all issues and determine the root cause of the failure.

-

Component-Level Refurbishment and Balancing: Our expert technicians meticulously restored or replaced damaged components. Crucially, all rotating parts were precision balanced to eliminate vibration, a key factor in extending spindle life and maintaining machining accuracy.

-

Final Run-In Testing: The fully rebuilt spindle underwent rigorous run-in testing following the manufacturer’s specifications. This final step guarantees that the spindle meets or exceeds OEM quality and reliability standards before it ever leaves our facility.

Why Choose FISCHER for Your GMN Spindle Repair?

When your production is halted due to a down spindle, you need more than just a quick fix—you need a reliable, long-term solution. By choosing FISCHER USA for your spindle repair needs, you gain:

-

Unmatched Expertise: Our technicians are trained to the highest standards, ensuring they can handle the complex geometries and tight tolerances of virtually any high-speed, high-precision spindle on the market.

-

Commitment to Quality: We don't settle for "good enough." Every repair, regardless of brand, is held to the same stringent quality control standards we apply to our own new spindles.

-

Reduced Downtime: Our efficient, process-driven approach and dedication to quick turnaround times help get your most critical machines back online faster.

Whether your spindle carries the FISCHER name or another manufacturer’s, our team is ready to keep your machines performing at their very best.

Ready to partner with a repair center focused on quality, uptime, and long-term support? Contact FISCHER USA today to discuss your 3rd party spindle repair needs.