Spindle System – Cooling System

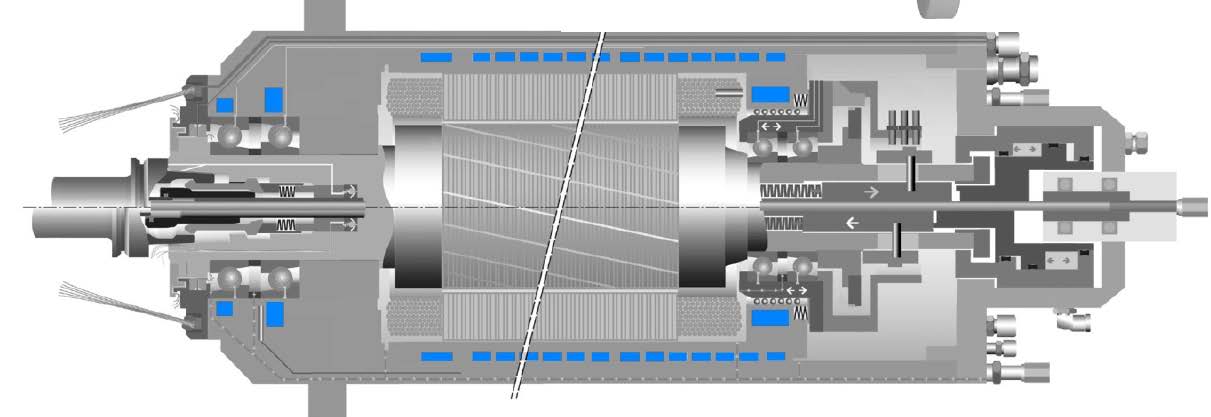

When discussing spindles, it is normal to not fully consider the sophisticated design of these products. Many people think of a spindle as a simple motor. While this may be true in some very limited cases, most modern high-speed machining spindles are made up of many high-precision components, complex internal systems, and peripheral support systems, including:

- High precision bearings and pre-load system

- High power density motors and drive system

- Precision-ground shaft

- Mechanical tool clamping system

- Hydraulic tool unclamping system and hydraulic supply unit

- Electronic sensor systems

- Encoder system

- Liquid-cooling system and chiller

- Lubrication system

- Pneumatic sealing system

The chiller unit is a crucial peripheral component within the spindle’s liquid-cooling system. Although some spindles are air-cooled, a liquid-cooling system is the most efficient means of heat removal. The chiller circulates a water/glycol mixture throughout the spindle, and this cooled (room temperature) fluid very efficiently performs the following functions:

- Removes heat from the motor to allow the highest power output at a continuous duty-cycle

- Removes heat from the bearings to help to achieve optimum bearing lifetime

- Removes heat from shaft and housing components to reduce thermal growth, and increase overall spindle accuracy and repeatability

The chiller system typically includes a reservoir (tank) for the cooling fluid, a pump, and a refrigerant-based cooling circuit for removing the heat from the fluid. Tubes (hoses) are used for transporting the fluid between the spindle and the chiller unit. Once inside the spindle, the cooling fluid flows through various channels and passages in the spindle housing components. The water/glycol mixture also helps to keep the cooling circuit clean and helps to guard against possible corrosion. The chiller in the spindle’s cooling system acts very similar to the radiator, water pump, and cooling fans in your vehicle to cool the engine.

The cooling capacity of the chiller unit should be roughly 20% of the spindle’s motor power (S1 kW rating). Other important points are:

- Strong fluid flow is important. There are many twists and turns on the interior of the spindle to reduce the flow rate, so a strong pump is required.

- A strong pump and strong fluid flow will result in a small temperature difference between the cooled fluid entering the spindle and the warmed fluid exiting the spindle. This small temperature increase is desirable. A weak fluid flow will result in the exiting fluid being much hotter, and this large temperature difference is undesirable, and can result in bearing problems and thermal growth issues.

- Large diameter delivery tubes/hoses should also be used for as long as possible between the chiller and spindle, stepping down to the diameter needed to match the spindle’s fittings near the spindle. This helps to improve the fluid flow.

- Cooling fluid should be delivered in the range of 20-24°C (68 – 75°F). Fluid that is too cold can cause internal and external condensation on the housing surfaces, causing corrosion and possible internal damage. Cooling fluid that is delivered too warm will reduce the spindle’s overall performance.

If you have any questions concerning your spindle’s liquid-cooling system, please contact us. Our team at FISCHER USA is well versed in the many systems and elements that make up a spindle, and we are always available to help you. From building spindles, to repairing spindles, to maintaining your spindle system, the team at FISCHER USA is knowledgeable, reliable and professional.