Spindle System - Motors

While FISCHER may be a global company, we have a design, production, assembly and service operations facility located in Racine, WI to fully support the North American market. We have a team of 60 highly skilled and focused individuals to provide you with your spindle needs.

While FISCHER may be a global company, we have a design, production, assembly and service operations facility located in Racine, WI to fully support the North American market. We have a team of 60 highly skilled and focused individuals to provide you with your spindle needs.

Spindles are complex mechanisms, with a lot of moving parts. Within a spindle there are 9 primary systems:

- Bearings

- Motors

- Shaft

- Clamping System

- Unclamping system

- Sensors

- Encoder

- Cooling System

- Sealing System

To understand motors, there are a few terms one may need to know:

- Current- flow of electricity, measured in amps (A)

- Voltage - speed of flow, measured in volts (V)

- Frequency - number of cycles in a time period, measured in hertz (Hz)

- Power - output, measured in kilowatt (kW, 1 kW = 1.34 mechanical horsepower)

- Torque - rotational force, measured in newton meters (N-m)

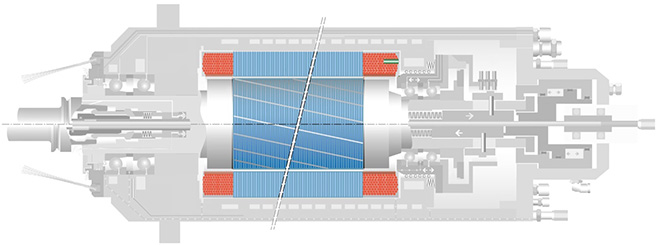

Our motors are designed for maximum performance with 3 phases and are either Asynchronous or Synchronous.

Asynchronous

Induction Motor (AC electric motor):

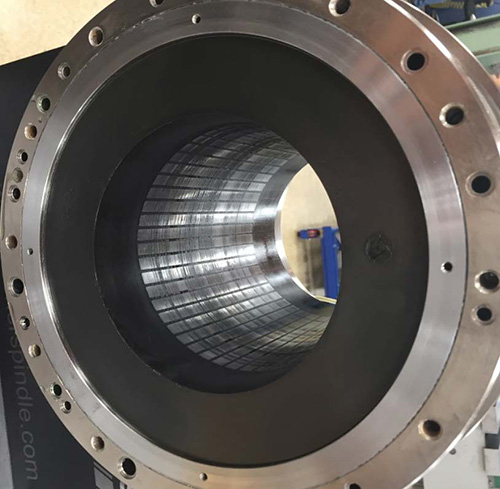

- Lamination stacks and copper bars on rotor

- Slip loss between stator (stationary part of motor) and rotor (moving part of an electromagnetic system in the electric motor)

- The rotor speed is always behind the magnetic field speed in the stator

- Overcome by increased current fed to motor

- Higher losses, runs warmer

- Open & Closed Loop

- Open – Input with no feedback

- Closed – Input, then feedback. Control system alters output to get desired results

Synchronous

Permanent Magnet Motor

- Newer Technology

- Rare earth metal magnets fixed to the rotor / shaft

- No slip loss (Closed loop only)

- Higher stiffness due to larger shaft OD (shaft diameter), more torque available lower speeds

Motors can be made from a variety of materials, including copper wires, carbon fiber as well as several others. Also, when thinking about the type of motor you need, remember to take in to account the following:

- What speed and torque are required for the application? If more torque is what you need lean towards Synchronous. If it's more speed with less torque needed then lean towards Asynchronous. If you need more speed, power & torque then Synchronous should also be your choice.

- Do you need tool changing / closed loop? If your answer is yes, then either Asynchronous or Synchronous could be a nice fit. If the answer is no, then Asynchronous should be the one you go with.

- What are the space limitations within the spindle design? Keep in mind that you have a more dense power to torque ratio with Synchronous motors.

No matter what kind of motor you use for your spindle needs, you can rest assured that our team will design what is best for you to your specifications & satisfaction. Contact us today to get started!