Spindle System - Shafts

Many people know the name FISCHER being synonymous with Precision, Speed, Power and Best In Class customer service. What many people do not realize is that we have been in our current location since 1941 with our sole focus on high performance spindles. We continually invest locally in our design, production, assembly and service operations to fully support the North American market. That being said, our team of highly skilled individuals have over 600 years of combined experience working with spindles.

Within a spindle there are 9 primary systems:

Within a spindle there are 9 primary systems:

- Bearings

- Motors

- Shaft

- Clamping System

- Unclamping System

- Sensors

- Encoder

- Cooling System

- Sealing System

The central and most critical component of these systems is the shaft. The shaft is essentially designed first and the rest of the spindle is then built around it. The shaft is designed to handle many functions and therefore has many considerations taken into account when being designed.

Material: It is imperative that the shaft is designed with a material that has high strength & rigidity, so that it can withstand machining loads and carry them to the bearings, with minimal deviation. The shaft must also be large enough to accommodate the needed tool interface (HSK diameter/size). The shaft material must be able to be hardened in order to increase wear resistance and allow for best grinding conditions. The shaft must also be resistant to corrosion, so as to preserve a good surface quality in wet environments.

Accuracy: In order for optimal performance, the shaft must be precision ground to tight tolerances. This is to achieve the optimal bearing life and minimal tool runout. In order to achieve this it is paramount that runout, diameter, concentricity and square-ness have tolerances of 1-3 microns. Our experienced team and state-of-the-art equipment are able to produce this level of accuracy every time.

Balance: Not only does the shaft need to be very accurate in size and shape, but the shaft must also be balanced to G1 or better to achieve minor vibration for optimum tool performance and bearing life. First the shaft is independently balanced as a separate component on a balancing machine, later the shaft and spindle's rotating assembly are “trim” balanced by adding small weights, when fully assembled into the spindle. Both steps are essential in achieving low vibration values.

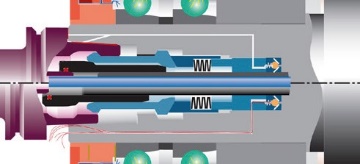

Clamping System: The shaft must be hollow with accurately designed internal contours to accommodate the drawbar and toolholder clamping system (HSK gripper system).

Taper Blow-Out: Incorporated into the shaft are internal air passages for the taper blow-out function. This will help prevent contamination when switching out tooling.

Length: Spindle shafts are designed to be as short as possible. The reason for this is to limit vibration, misalignment, and natural frequency problems. For high-speed applications short shafts are desired, however, the length is generally determined by the required motor power/torque. In most high-speed spindle designs, the rotor is mounted directly on the shaft (roughly in the center, between the bearing journals), so the rotor length directly affects both the bearing spacing and overall shaft length (longer rotors/stators = greater power/torque).

Tooling Affect: When long tooling is added to the spindle, it then has the potential of lowering the natural frequency into the spindle’s operating speed range.

Vibration: If a long tool is operated at or near the natural frequency, the tool will then vibrate uncontrolled in a “whipping” mode-shape. This vibration may cause the following:

- High vibration and potential bearing damage

- High bending forces at the HSK interface may cause: possible clamping system failure and tool ejection

- High bending forces at the base of the tool and possible tool breakage

Spindle shafts are designed to function at a fundamental frequency (in hertz [Hz], defined as one cycle per second) that is greater than the maximum rotational speed of the spindle (in Hz), with ample margin.

With spindle repairs from FISCHER USA you can rest assured that quality and consistency are a must. Contact us today for any of your spindle needs whether for a new application or repair service.