Spindle System – Unclamping System

For over 80 years, FISCHER USA has been known for its Swiss quality craftsmanship of spindles by its confident and reliable team. We also provide our spindle repair services that include in-house precision manufacturing, reverse engineering and full inspection capabilities. Our team will fully test your repaired spindle and ensure it operates just as it would when it is on your machine.

Our team is well versed in the various parts of spindles:

- Bearings

- Motors

- Shaft

- Clamping System

- Unclamping System

- Sensors

- Encoder

- Cooling System

- Sealing System/Requirements

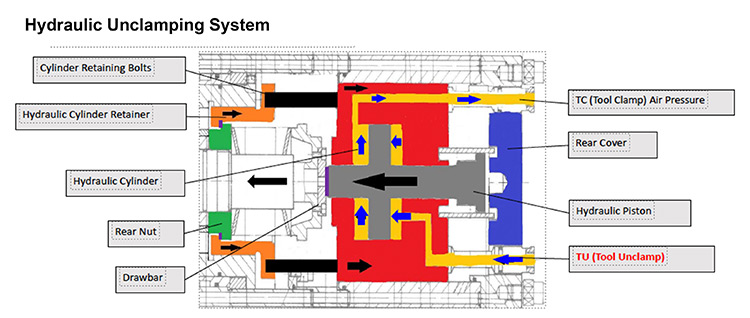

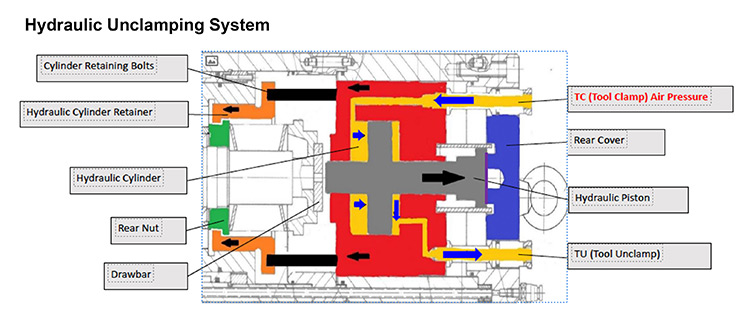

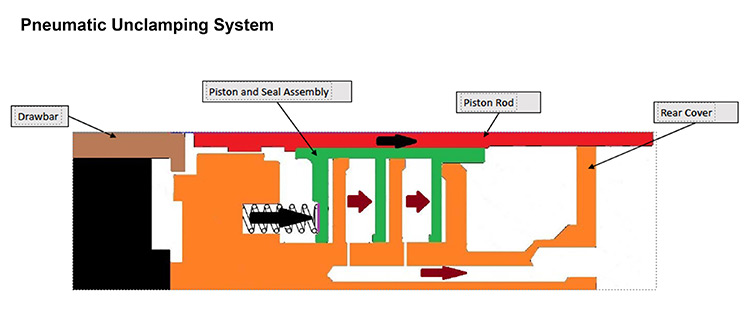

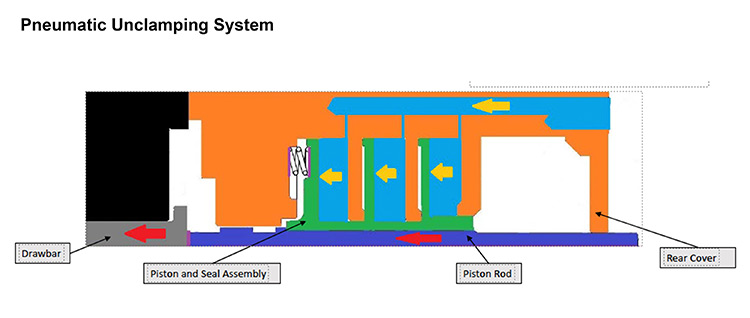

The Unclamping system is yet another important component into the whole of a spindle, when it is properly functioning. The unclamping system typically consists of two types of unclamping units that are used in an Automatic Clamping System: Hydraulic (fluid actuated) and Pneumatic (air actuated).

Unclamping systems are also usually:

- A separate unit that is either mounted on or internally to the body of the spindle

- Actuated using a separate peripheral system

- May house some or the entirety of the tool position sensors, for feedback as to what position the system is in

- HSK, Steep Taper, and Direct Shank clamping are possible interfaces that use automatic unclamping

Unclamping systems consist of double acting cylinders which require fluid or gas for them to properly move in two directions. Both the Clamp and Unclamp systems have the capacity for fluid or gas.

Unclamping Hydraulic System Technology consists of:

- Most compact units have the capabilities of high force

- Self contained units

- Pressurized fluid is used for actuation or release

- Cylinder have pistons and seals

- Can be either dual or single sided; meaning hydraulic pressure may be used on one or both sides of the cylinder

- Needs a separate peripheral unit (usually stand alone) for use

- Machine will sometimes have single hydraulic system using series of valves to actuate unclamping unit

Unclamping Pneumatic System Technology consists of:

- Uses pressurized air for actuation or release

- Self contained unit

- Usually comprised of a stack of pistons with seals in a segmented or single housing

- Needs much larger units vs hydraulic unit to generate a similar pressure

- Usually single sided or single acting type cylinder

- Pressure used only to release tool. Springs on other side of pistons return to position once pressure is released

Hydraulic Unclamping Design Aspects & Considerations:

- Use of hydraulic cylinder is considered more when overall spindle side must be as compact as possible

- Cylinder can generate much higher force in a more compact form, due to properties of hydraulic system. Much higher pressures (>100 bar) for overcoming pressure of clamping system to release tools

- Typically used on larger HSK size clamping systems (HSK-50 to HSK-125)

- As higher pressures can be used, actuation of tool release can be much quicker vs pneumatic systems

- System is relatively low maintenance, even complete stand alone systems

Pneumatic Unclamping Design Aspects & Considerations:

- Uses shop air pressure, typically present on all machine types

- Less force is generated in given area, so cylinders are typically larger to create enough force to release tool

- Typically for use only on small spindles with interface up to HSK-50 or ISO-40

The following diagrams show the functions and movements of the varying parts of both the Hydraulic and Pneumatic Unclamping Systems.

No matter which Unclamping system you choose to go with for your spindle system needs, you will be in good hands should you ever require repairs. FISCHER USA has expanded spindle repair services over the past decade to include all makes and models, such as GMN, IBAG, Kessler, Weiss, Makino, and Mazak, to name a few. Contact us today for all of your high-speed spindle repair needs!