What to Know About Bearings

Bearings are used in a lot of different machines and equipment, but how much do you really know about them? The general definition for bearings is that they are used to prevent metal-to-metal contact between two parts by reducing friction and constraining relative motion to only the desired motion. By that definition, we can see the importance of them in many machines, especially high-speed spindles. With over 20,000 rpm, metal-to-metal contact would lead to a large amount of wear on the various parts, which would then result in repairs and replacement.

High-speed spindles almost always utilize angular contact bearings. These bearings allow for force to be passed through the races at an angle. They then have the ability to handle both radial (side) and axial (thrust) loading conditions within one bearing. Their specific and perfectly engineered design gives them the ability to operate at high speeds. Another factor that is based off of the need to produce high speeds is the materials used for the bearings.

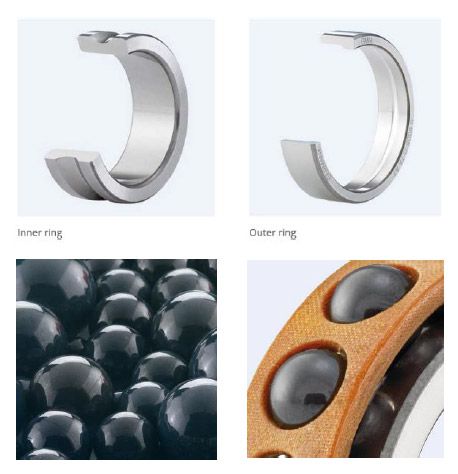

The bearings used are a hybrid ceramic, which means the the raceways are made of steel, or highly hardened chromium steel, while the balls are a silicon nitride ceramic. Ceramic provides much less mass in the same size ball, allowing for higher speeds. Another benefit of ceramic vs steel balls is that they have higher stiffness and durability, which ensures a longer lifetime. As ceramic construction leads to less vibrations and a more perfectly round ball, the bearings are able to operate at lower temperatures and cause less contamination. These ceramic balls are then held in place by a phenolic, plastic or carbon-fiber reinforced cage to help hold them in place. Those materials are usually used in place of a steel or brass cage in order to further reduce friction and mass to allow for high speeds and reduced temperatures and wearing.

Even with these engineered designs and correctly selected materials, the bearings are known to break or wear down. As part of the inspection and repair process for your high-speed spindle, we will inspect the bearings and replace them to ensure the proper reliability and performance is achieved. If you feel you may have a spindle experiencing bearing problems, please contact us today.